The oil circulating in the heart of manufacturing and industrial machinery doesn’t just keep components working efficiently – it’s a pointer to their condition. By analysing a sample of oil obtained without dismantling or stopping the machine, our experts can monitor the state of its engine, helping optimise machine maintenance to avoid unexpected shutdowns and costly emergency repairs.

Anticipate issues before they appear

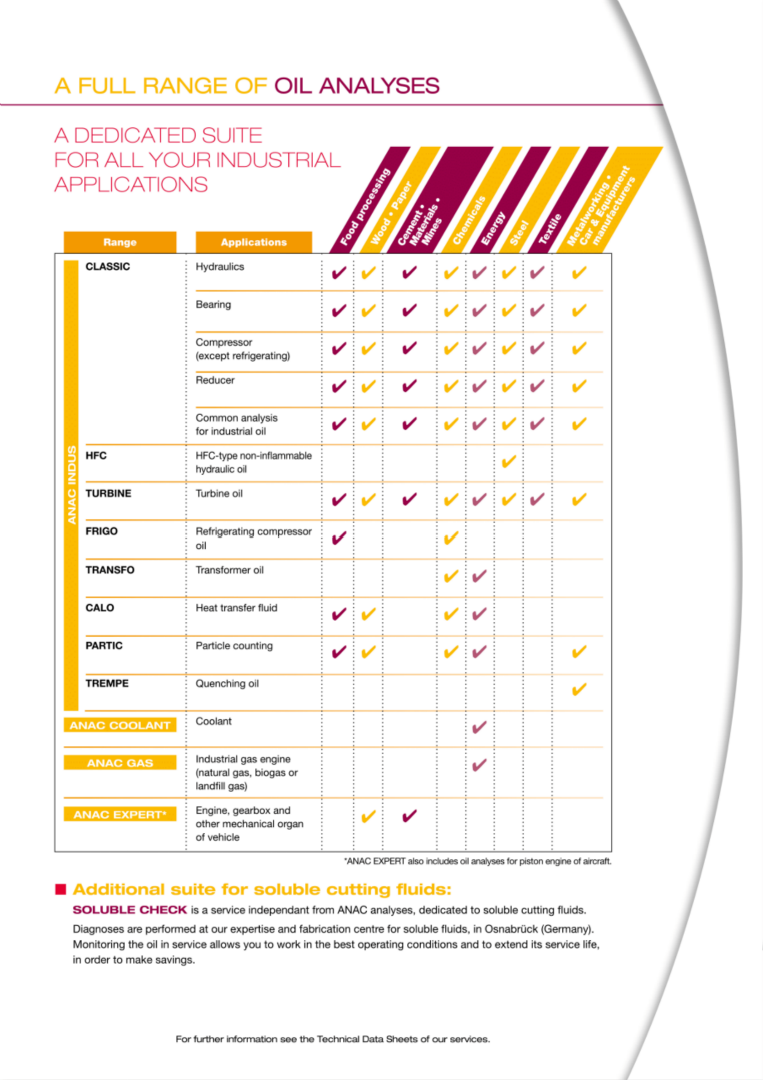

The ANAC INDUS oil analysis program allows engineers to switch from curative to predictive maintenance. Plan production stoppages for maintenance at the best time to optimize the life of parts and lubricants in service, improving the productivity of machines and lowering their maintenance costs.

Expertly tailored industrial oil analysis

All oil analyses are performed in TotalEnergies’ cutting-edge laboratories using processes honed by 30 years of fluid diagnosis expertise. We understand every industrial process is specific, so users can rely on our specialists to recommend a program of oil analyses dependant on their equipment and operational conditions. Lastly, for TotalEnergies lubricant users, ANAC is the best service to assess the residual performance of in-service oils, as we design their formulation.

Quick, clear oil reporting

When ready, diagnoses are available for consultation via a secure extranet and can also be delivered by mail, email or fax in case of emergency. Understanding each oil analysis is easy, thanks to simple tabular layouts and colour coding that lets anomalies be quickly highlighted, and for users of TIG XP5 maintenance software, results can be directly imported, helping users follow analysis histories and further help plan maintenance.

What are the benefits of ANAC INDUS?

By choosing ANAC INDUS, machine operators can enjoy a range of benefits:

- Saves maintenance costs

- Decreases the occurrence of production stoppages

- Helps maintenance operation planning

- Improves equipment reliability and performance

- Lengthens machine lifetimes

- Extends oil drain intervals

ANAC INDUS is designed to make manufacturing and industrial operations more efficient and cost-effective. View the TotalEnergies range of industrial lubricants or contact our team for more information about ANAC.