What is transformer oil?

Transformer oil is used to insulate high-voltage electrical infrastructure such as transformers, capacitors, switches and circuit breakers. Transformer oils are designed to operate effectively at very high temperatures, cooling, insulating, and stopping corona discharges and arcing.

Transformer oils surround the core and windings of transformers, preventing wiring and cellulose-based insulation from oxidising, corroding and becoming less effective. With excellent dielectric strength, chemical stability and thermal conductivity, transformer oils circulate between the core and radiators, reducing the temperature of the infrastructure.

What is the temperature of transformer oil?

Instead of measuring maximum temperature to gauge efficiency and capability, transformers’ temperature rises are used as a guide, with lower temperature rise standards better at coping with overloads.

Liquid-filled transformers come with standard rises of 55°C or 65°C, based on a maximum average temperature of 40°C. Some hotter spots may exist within the transformer though. That means liquid-filled transformers have a maximum average operating temperature of 105°C. Insulation winding insulation is typically rated to 220°C.

If you are unsure of your transformer oil’s temperature rise standard, consult your documentation or contact the manufacturer.

What is the chemical name of transformer oil?

Transformer oils come in a wide range of types, meaning there isn’t a single chemical name for all oils. Most are comprised of organic compounds including paraffins, napthenes, olefins, aromatics and natural and synthetic esters, although oils based on silicone and fluorocarbons are also sometimes used.

What is the BDV of transformer oil?

The BDV of a transformer oil differs depending on the type of oil and its condition. BDV stands for Breakdown Voltage and is used to measure the dielectric strength of transformer oil. The higher the value, the lower the presence of contaminants.

Minimum breakdown voltage values typically lie between 30-40 kV, dependent on the levels of moisture within the oil – the more moisture, the lower the breakdown voltage.

If you are unsure of your transformer oil’s breakdown voltage, consult your documentation or contact the manufacturer.

Transformer oil grades

Transformer oils are graded in line with international standards such as IEC 60296. Within these, there are usually a range of classes, defining transformer oils usage, additives, lowest cold start energizing temperatures (LCSET) and more. Contact our experts to learn more about the specific grades of TotalEnergies' transformer oils.

What are TotalEnergies' electrical transformer oils?

TotalEnergies' transformer oils are used in oil-filled electrical transformers, protecting their components from breakdown and overheating in extremely hot, high-stress conditions.

Preventing short-circuiting and reducing wear, they lower oil, maintenance and replacement costs, optimising the performance of electrical equipment and ensuring grid stability.

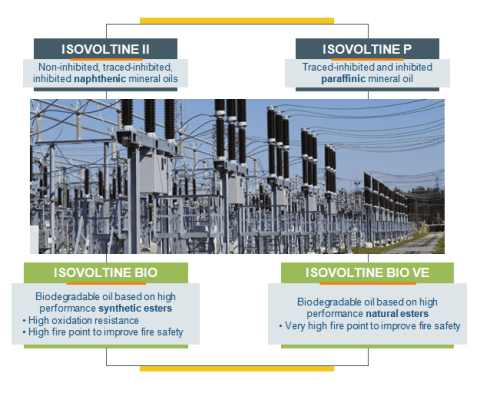

TotalEnergies' insulating electrical transformer oils include:

- Isovoltine II – Non-inhibited, traced-inhibited and inhibited naphthenic mineral oils.

- Isovoltine P – Trace-inhibited and inhibited paraffinic mineral oils.

- Isovoltine Bio – Biodegradable oils based on high-performance synthetic esters.

- Isovoltine Bio VE – Biodegradable oils based on high-performance natural esters.

Why choose TotalEnergies' transformer oils?

Energy grids and power systems are relied upon to constantly perform, whether they’re providing electricity for a business or home life. Transformers are a key part of this power infrastructure, but they need to be insulated with lubricants to function correctly and not overheat from the extreme voltages passing through them.

TotalEnergies premium industrial transformer lubricants provide this protection, cooling transformer components such as the core and windings, insulating them. This ensures that wear and corrosion are protected against, as well as dangerous overheating and the breakdown of transformer materials.

Customers can also benefit from TotalEnergies' support services to get the most out of their transformer oils, including ANAC, the oil analysis service that helps businesses identify anomalies in production chains to boost productivity and performance. All part of our energy and power offerings.

Totalenergies' transformer oils’ Key features and benefits

TotalEnergies' insulating oils push the boundaries of performance with the following features and benefits:

- Excellent insulating power – Protecting components and keeping sites and personnel safe.

- High oxidisation resistance – Prolonging oil and component lifetimes.

- Very high flash point – Improving fire safety to protect staff and equipment.

- Reduces sludge build-up – Reducing maintenance frequency.

- Superior insulating properties – To protect components and reduce replacement costs.

- Contains inhibitors – To ensure oxidisation resistance.

- No sulphur – Reducing corrosion.

- High purity levels – Lowering temperatures and improving power factors.

- Superlative cooling properties – Due to excellent fluidity and heat transfer.

- Biodegradable oils available – To minimise environmental impacts.

- High dielectric breakdown voltage

- High volume resistivity

- High interfacial surface tension

- No polar substances

TotalEnergies' transformer oils are relied upon by industrial and utility businesses the world over. For more information on how they can safeguard your power equipment.