What is cutting fluid?

Cutting fluid lubricates, cools and protects metalworking processes such as machining, grinding, finishing, broaching and cutting. It is used to extend the performance and lifespans of cutting tools, keep machined materials in perfect condition, prevent corrosion and rust, rinse away deposits and chips, and safeguard staff, tools and worked products from contamination.

What is cutting fluid made of?

Cutting fluid comes in a range of formulations designed for specific metalworking processes. There are four main types:

-

Neat oils – mineral oil-based cutting fluids used more to lubricate than cool.

-

Macro emulsions – featuring mineral oils and emulsifiers designed to offer reliable cooling and lubrication.

-

Micro emulsions – combining synthetic compounds such as phosphate esters, mineral oils and emulsifiers, micro emulsion cutting fluids protect from corrosion and contamination while offering great cooling and lubrication.

-

Water-based coolants – fully synthetic cutting fluids without oils that offer the best possible cooling and anti-corrosion performance.

Cutting fluids from TotalEnergies

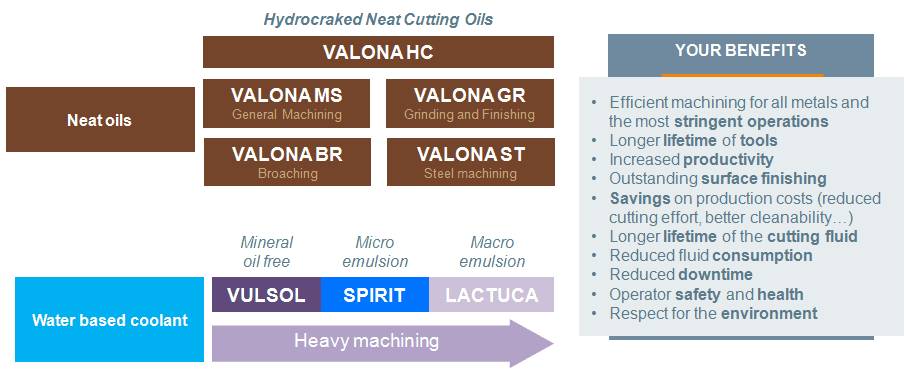

TotalEnergies' range of premium metal working cutting fluids span and protect a very wide range of cutting tasks:

-

Folia – Metalworking fluids without emulsifiers or mineral oils for multiple applications.

-

Valona HC – Hydrocracked neat oil for cutting tools.

-

Vulsol – Mineral oil free water-based coolant for cutting tools.

-

Spirit – Soluble microemulsion lubricant for cutting equipment.

-

Lactuca – Soluble macroemulsion lubricant for general machining equipment.

-

Martol – Soluble deformation oil for steel and aluminium cutting.

-

Drosera – Mineral multipurpose oils for high speed cutting tools.

Our neat cutting oil: Valona Bio

Valona MS 7010 BIO is a vegetable neat cutting oil designed for severe machining mainly. It is a biosourced and biodegradable product operating on ferrous and non-ferrous materials.

The advantage of this fluid is its safety and environmental friendliness. It offers the advantage of no skin irritations and displays low mist emissions.

This neat cutting oil offers excellent tool protection and increase tool lifetime. The fluid is resistant to strong oxidation. Valona MS 7010 Bio is a multi-purpose fluid, suitable for the various stages of the machining process, namely: sawing, milling, turining, drilling, reaming, tapping, threading and broaching.

The advantage of this Bio product is its formulation with no hazardous component and its ability to enhance excellent cutting performance compared to conventional neat oils.

Our soluble oil: Spirit X

Spirit 7000 X is a biocide-free, mineral oil-free micro-emulsion technology specially designed for heavy machining of cast iron, steel, aluminium and many others.

The cutting fluid is particularly suitable for metalworking. It is compatible with aluminium with improved surface finish. It offers a very high lubrication as well as a particular resistance to corrosion. Spirit 7000 X contains specific EP additives to optimize lifetime of the tool and surface aspect of the metal parts. The specificity of the Spirit X range is also its absence of hazardous pictograms. It is specified to ISO 6743-7; ISO-L-MAF.

Our bio-sourced soluble oil: Folia

Folia B 7000 is a bio-sourced water-based fluid, mineral oil-free and emulsifier-free, which shows excellent cooling and lubricating properties.

Folia B 7000 is a lubricant formulated with the aim of being safer. Its particularity is that it does not present any pictograms or hazardous component, which reduces the risk of skin irritations. This new product offers better performance for both operators and their environment thanks to innovative technologies that replace conventional oils with bio-based polymers. This range is part of TotalEnergies's commitment to develop reliable fluids that meet current safety and environmental standards. This new fluid meets three major challenges - health, safety and environment.

The fluid allows to maintain an excellent stability in the cutting phases. The product increases productivity and cutting speed for an equivalent surface quality compared to a conventional fluid.

Why choose TotalEnergies' cutting fluids?

Whatever the cutting task, productivity and production can be jeopardised if an operation doesn’t have fluids specially developed to suit the tools and materials, but with TotalEnergies' cutting lubricants, you can be sure your lubricant is an asset to production.

If you want a metal cutting fluid that improves the performance of your cutting tools, protects them from wear and saves you money in the process, TotalEnergies' cutting fluids are an excellent investment. With a raft of features and benefits, they’re high-quality oils that won’t let you down. Part of the Total Metalworking lubricant range.

TotalEnergies cutting fluids key features and benefits

TotalEnergies' cutting fluid range offers several features and benefits:

- Efficient machining for all metals – Even in the most stringent operations.

- Longer lifetime of tools – Reducing costs and increasing productivity.

- Outstanding surface finishing – Improving broaching quality.

- Excellent cooling power – Prolonging the operation of machinery.

- High efficiency in all applications – Providing multipurpose performance.

- Excellent pressure resistance – Protecting tools from metal wear and corrosion.

- Exceptional anti-wear properties – Reducing tool change frequency.

- Low volatility – Minimising misting and oil consumption.

- Transparent product – For easier machining.

- Low or no odour – For a more pleasant working environment.

- Quick drying action – To minimise downtime.

For more information on TotalEnergies' range of machining cutting fluids or to make an order, contact our experts.