High-performance lubrication for cement and materials machiner

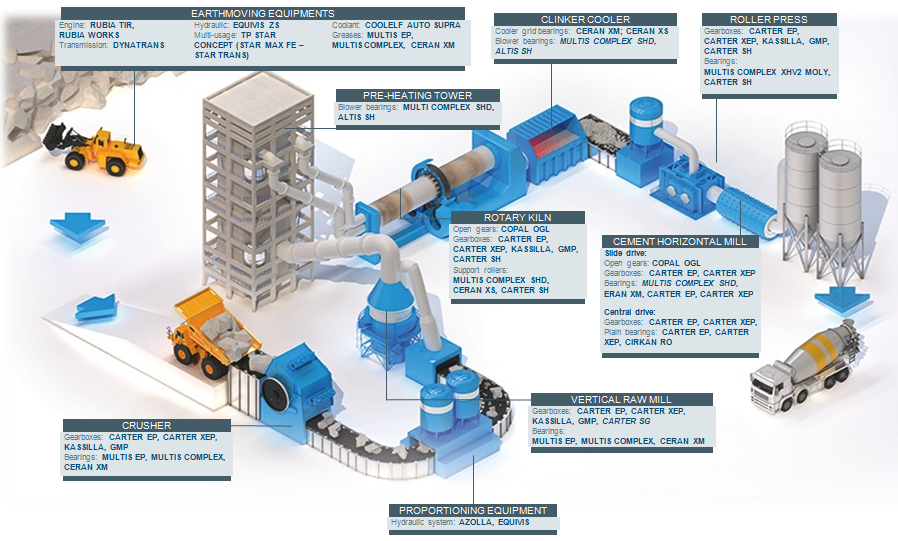

With decades of experience working with cement manufacturers, TotalEnergies Industrial Lubricants has developed a comprehensive range of lubricants for cement production covering every stage of the process. The cement lubricants we supply are highly durable and capable of facing the severe operating conditions, extreme temperatures, heavy loads and high pressures experienced by cement-making machinery.

Each product delivers on quality too, protecting equipment, extending its working life and minimising the risk of production stoppages, and thanks to our drive to innovate, we offer lubricants that reduce the environmental impact, fuel and lubricant consumption of machinery.

Cement lubricants for every step of the production process

TotalEnergies’ Cement machinery lubricant range covers all industrial processes that comprise cement production, including lubricants for hydraulics, engines, gearboxes, bearings and much more. From earthmoving and crushing, to heating and cooling, all the way to milling and pressing, every lubricant in the range has been designed to improve machinery performance and lengthen drain intervals, protecting components from temperature and pressure extremes.

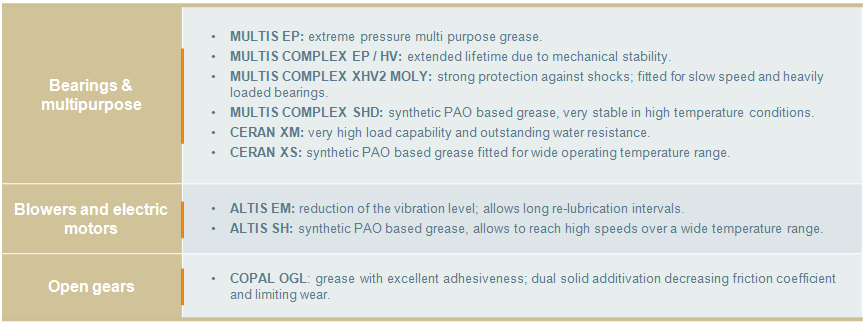

High-performance cement greases

TotalEnergies’ cement greases cover bearings, blowers, electric motors and open gears, lengthening mechanical lifetimes and reducing maintenance costs by reducing vibrations, resisting heat and pressure, and protecting against shear, shock, oxidisation and corrosion. With synthetic and mineral formulations and featuring specially optimised additives, there’s a cement production grease for every purpose.

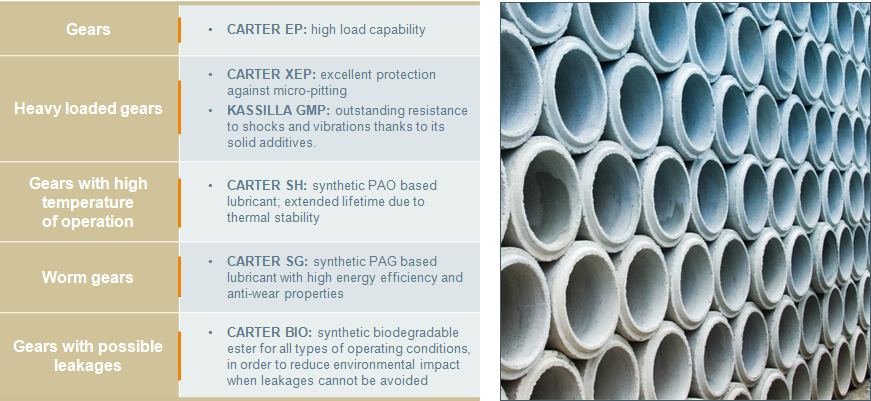

A comprehensive range of cement gearbox oils

Cement manufacturing processes involve a huge range of gearboxes operating under varying stresses. To ensure cement producers can keep their open and closed-gearboxes working perfectly, even under tremendous loads, shocks and vibrations, TotalEnergies has developed gearbox oils for all uses and environments.

View Total’s RUBIA WORKS range of general-purpose equipment lubricants, or contact the TotalEnergies team for more information on the wide range of specialised cement lubricant.

IOEM approvals

- Flender Siemens

- FLSmidth

- Fives FCB

- Loesche

- Polysius

- KHD Humboldt Wedag

What our customer say?

Our references

- Lafarge

- Holcim

- Heidelberg

- Italcementi Group

- Sinoma

- Vinaconex

- Cemex

- Rio Tinto

- Lhoist

- Titan

TotalEnergies has been our lubricant supplier since 2005. We chose TotalEnergies because of the great performance of products (such as Copal OGL 0, Carter EP 150, Carter EP 220, Carter EP 320 and TotalEnergies Lex 2), and services including commercial support, technical support and the ANAC lubricant diagnostic service. The successful collaboration between TotalEnergies and Holcim means that TotalEnergies is our brand of choice.

We reviewed the manuals for the FCB equipment we have with TotalEnergies’ technical engineers and found that the recommended circulation oil is ISO-VG 320 for the shoe bearings in cement mill nine. TotalEnergies recommended Cirkan 320 to maintain temperatures within FCB’s recommended range, to protect the life of our bearings and minimise downtime. TotalEnergies Cirkan 320 maintained the OEM recommended temperature of 62°C extending bearing life and reducing lubrication costs by 20%.